Borescope & Eddy Current Inspections

Get a FREE Site Survey Today!

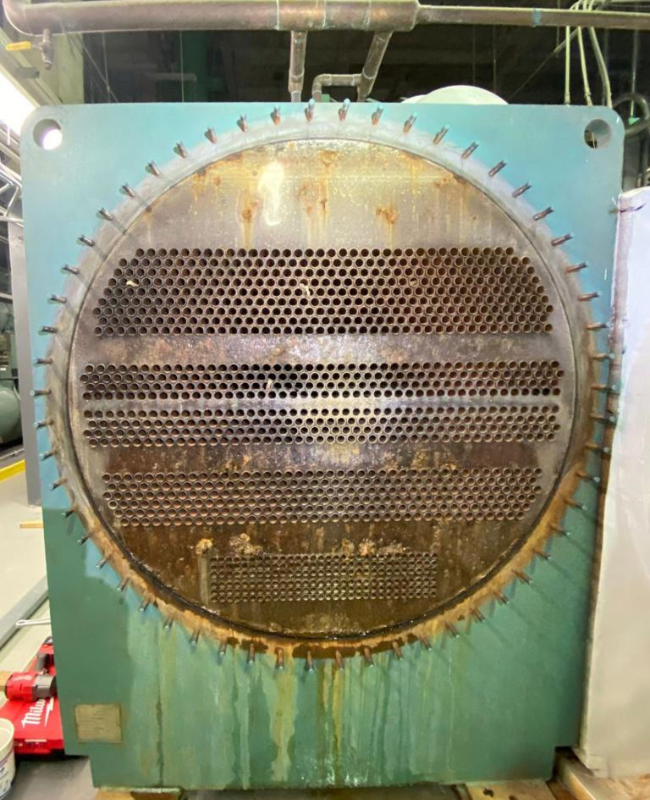

Borescope Video Inspection

Video Boroscope equipment can be a valuable tool in enhancing the quality of tube inspections. General borescopes can truly reveal the extent of tube damage or fouling using high-resolution, magnified images of the inside of tubes that can be indispensable in determining the next step in a maintenance or repair solution. Our technicians can set up these cameras directly onsite, allowing real-time viewing of the images the borescope cameras see. We can also format these videos onto flash drives or DVD’s for future records. This allows immediate feedback of the situation inside your tubes, and can establish a clear point of comparison for any future inspections to see the progress of any changes, positive or negative.

Eddy Current Inspections

Eddy current inspection is an efficient and precise non-destructive test method. This type of inspection is particularly helpful to evaluate heat exchangers and aircraft parts and components. Eddy current utilizes a set of bobbin coils that can detect and size degradation mechanisms in tubing and is able to determine between an ID and OD originating flaw. Most non-ferrous tubing applications will utilize this method of testing, unless certain damage mechanisms are known to exist such as circumferential cracking, where Eddy current array would be a more appropriate testing technique.

If your chiller has been in use for more than three years, it should be tested for potential tube damage, and all heat exchangers should have eddy current tube analysis performed at least every three years.

For OEMs, we can eddy test your heat exchangers at the factory prior to shipping. Our baseline testing will ensure that your products are free of manufacturing defects and will perform at their peak.

Borescope Video Inspection

Eddy current inspection is an efficient and precise non-destructive test method. This type of inspection is particularly helpful to evaluate heat exchangers and aircraft parts and components. Eddy current utilizes a set of bobbin coils that can detect and size degradation mechanisms in tubing and is able to determine between an ID and OD originating flaw. Most non-ferrous tubing applications will utilize this method of testing, unless certain damage mechanisms are known to exist such as circumferential cracking, where Eddy current array would be a more appropriate testing technique

If your chiller has been in use for more than three years, it should be tested for potential tube damage, and all heat exchangers should have eddy current tube analysis performed at least every three years.

For OEMs, we can eddy test your heat exchangers at the factory prior to shipping. Our baseline testing will ensure that your products are free of manufacturing defects and will perform at their peak.

Condenser Tube Cleaning & Evaporator Tube Cleaning

Chiller efficiency is affected more by the cleanliness of heat transfer surfaces than any other single factor. Given that a chiller typically can have several miles of tubing making up the condenser and evaporator, it makes sense to keep chiller tubes as clean as possible by using a combination of water treatment and planned outages for tube cleaning and other major maintenance tasks. As contaminants accumulate on chiller tube surfaces, efficiency declines rapidly. Contaminants can range from mud, sand and algae to hard mineral scales, which increase thermal resistance and cause the chiller to work harder to meet demand, thereby consuming more energy.

Fouling Factor

Loss of Efficiency

%

%

%

%

%

Increased Power Needed

%

%

%

%

%

We Provide Water Solutions For You!

Talk to us today!

Company

Our Services

Location

7901 SW 6th Court, 3rd Floor, Plantation, FL 33324

Mailing Address:

7027 W. Broward Blvd, #337, Plantation, FL 33317