Borescope & Eddy Current Inspections

Get a FREE Site Survey Today!

Advanced Technology

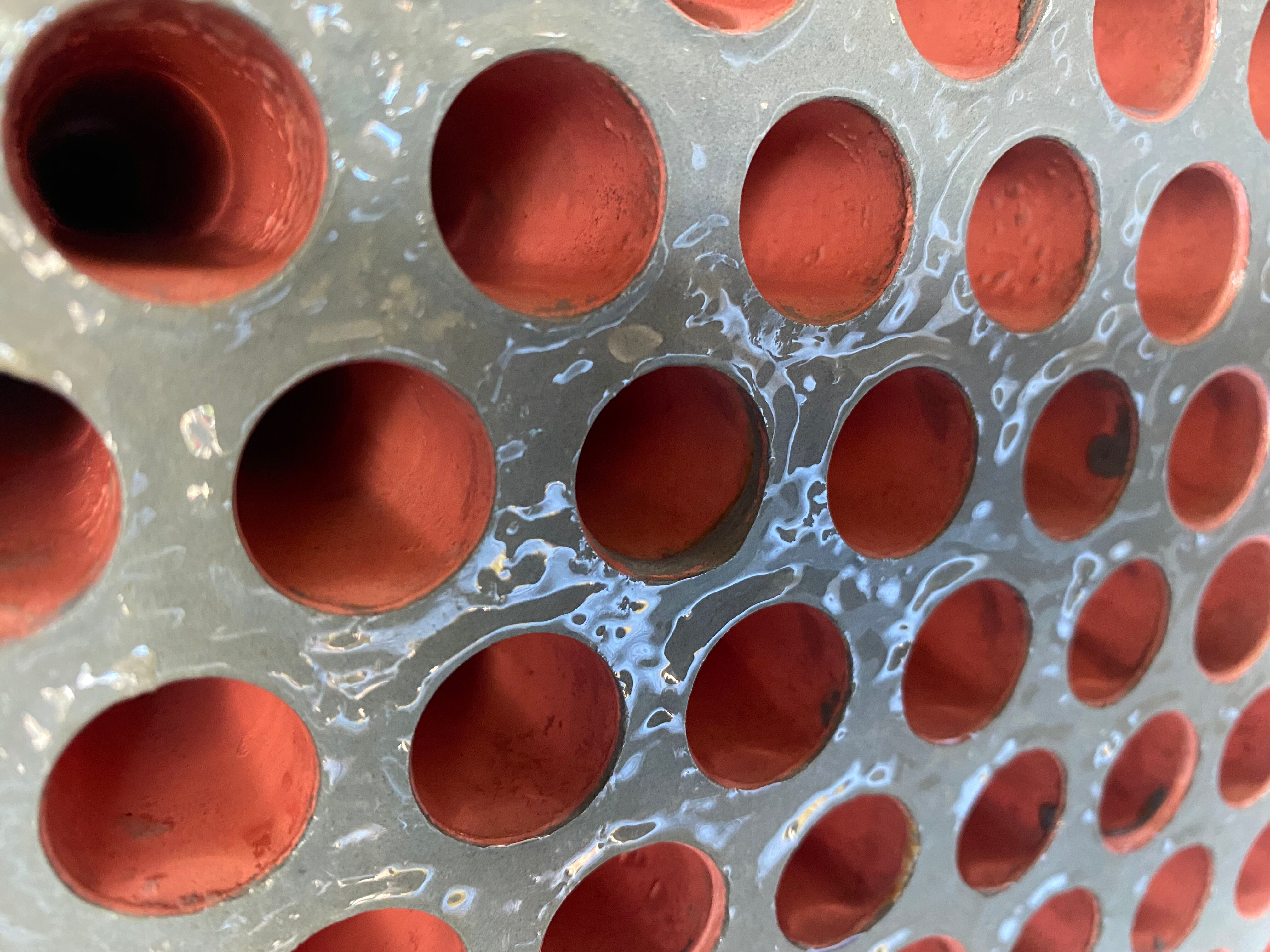

Borescope Video Inspection

Video Boroscope equipment can be a valuable tool in enhancing the quality of tube inspections by providing high-resolution, magnified images of the inside of tubes.

Borescope Video inspections will help you spot minor issues before they become major problems. You’ll save time and money by treating easy-to-fix problems the moment they arise.

Our borescope inspection can determine problems with welds, detect corrosion issues, identify blockages, examine for presence of cracks, as well as other discontinuities.

Our technicians can set up these cameras directly onsite, allowing real-time viewing of the images the borescope cameras see. We can also format these videos onto flash drives or DVD’s for future records.

Advanced Technology

Eddy Current Inspections

Eddy current inspection is an efficient and precise non-destructive test method. This type of inspection is particularly helpful to evaluate heat exchangers and aircraft parts and components.

Eddy Current Inspections are one of the most versatile forms of NDT testing in terms of portability and flaw detection. It is safe, effective, and efficient, capable of detecting even easily-overlooked defects.

Our borescope inspection can determine defects such as cracking, corrosion, erosion, material degradation and thickness loss. For OEMs, we can eddy test your heat exchangers at the factory prior to shipping. Our baseline testing will ensure that your products are free of manufacturing defects and will perform at their peak.

Eddy current testing probe uses a copper wire injected with an electrical current. The wire produces a magnetic field that oscillates at the same frequency as the current running through the copper wire. When you move the testing probe near conductive materials, currents opposed to the ones in the copper wire are induced in the material.

Condenser Tube Cleaning & Evaportor Tube Cleaning

Thermal Insulation

Sediment

Biological Growth

Algae

Atmospheric Contaminants

Corrosion

Industries Served

Hospitals

Schools & Universities

Government Facilities

Distribution Centers

Data Centers

Manufactuing Facilities

Hospitality

Prisons

Senior Living Communities

Banks

We Provide Water Solutions For You!

Talk to us today!

Company

Our Services

Contact Us

7027 W. Broward Blvd, #337, Plantation, FL 33317