Industrial Wastewater Treatment

Schedule a Free Site Survey!

At Florida WPS, we offer a comprehensive approach to industrial wastewater treatment that maximizes equipment performance while minimizing costs and environmental impact. Our team of experts will guide you through the process of selecting, applying, and monitoring a customized chemical program tailored to your specific needs.

By conducting a thorough system audit and testing, we can design a wastewater treatment process that optimizes chemical usage, effluent flow rates, and off-site treatment costs, all while ensuring the highest standards of environmental sustainability. Our expertise extends to water reuse systems and zero-liquid discharge, giving you the peace of mind that comes with knowing your effluent system is operating at peak efficiency.

With our specialized knowledge of organic and inorganic chemicals, we can help you reduce your discharge costs and achieve optimal results for your effluent system. Our wastewater specialists have worked with a variety of industries, including metals, oil and gas, automotive, food and beverage, mining, steel manufacturing, and pulp and paper processing, and have experience with unique treatment processes tailored to each sector.

Let us help you achieve your wastewater treatment goals with environmentally-efficient and sustainable methods that optimize your system’s performance and cost-effectiveness.

Defoamers

If foam is a problem in your industrial water systems, Florida WPS has you covered with our comprehensive product line of defoaming agents. Our team can help you select the best defoamer technology to optimize your system and ensure smooth operating conditions.

Our defoamer products are designed to eliminate foam in a variety of applications, including boilers, cooling towers, and effluent systems. We use a range of defoaming agents, including surface tension reduction and bubble-wall destabilization products, each tailored to specific requirements. Our products are formulated with a variety of constituents, including silicone, oil-based, ester-based, water-based, and polymeric components. This ensures that we can provide the best-suited defoamer for your specific needs.

Oil Removal

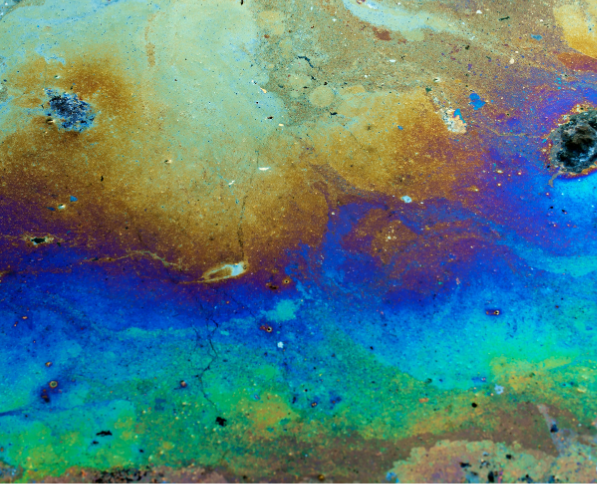

At Florida WPS, we offer a comprehensive range of industrial wastewater treatment programs that include a complete portfolio of surfactants, coagulants, and emulsion flocculants specifically designed for oil removal applications. Our team of experts can help you select the best treatment program to optimize the removal of oil and other contaminants from your wastewater system.

Our surfactants and emulsion flocculants are formulated to effectively break down and separate oil from the water, while our coagulants help to aggregate the separated oil for easier removal. We can customize a treatment program to meet the specific requirements of your industry, ensuring that your wastewater system operates at peak efficiency while reducing your environmental footprint.

Oil Removal

At Florida WPS, we offer a comprehensive range of industrial wastewater treatment programs that include a complete portfolio of surfactants, coagulants, and emulsion flocculants specifically designed for oil removal applications. Our team of experts can help you select the best treatment program to optimize the removal of oil and other contaminants from your wastewater system.

Our surfactants and emulsion flocculants are formulated to effectively break down and separate oil from the water, while our coagulants help to aggregate the separated oil for easier removal. We can customize a treatment program to meet the specific requirements of your industry, ensuring that your wastewater system operates at peak efficiency while reducing your environmental footprint.

Emulsion Breakers

Florida WPS offers a range of emulsion flocculants, which are tiny polymer beads that are suspended in water and emulsified in oil. These beads contain concentrated polymer and are kept small and well-dispersed by a surfactant, which prevents them from coalescing into larger droplets that could lead to product instability. Emulsion flocculants are typically made up of copolymers of acrylamide and a charge-bearing monomer, with the degree of charge on the molecule determined by the ratio of monomers. Anionic flocculants use acrylic acid to provide the anionic charge, while cationic flocculants use AETAC as the cationic monomer.

Because the hydrogels in emulsion flocculants are made up of tightly-coiled polymer chains, they require mixing energy and time to fully contact with the water and uncoil. The polymer chains may be cationic, anionic, or nonionic, with varying charge weights. A higher-charged polymer will uncoil faster than a low-charged or uncharged polymer, making the degree of charge an important factor in the effectiveness of the flocculant.

Metal Removal

Our comprehensive range of products is designed to address the critical issue of heavy metal removal from wastewater. By utilizing our industrial wastewater treatment programs, you can effectively remove heavy metals in all discharge pH ranges, saving time and chemical usage. Ensuring compliance with discharge requirements for constituents such as iron, lead, copper, chromium, nickel, and manganese is essential to prevent environmental contamination and promote sustainable business practices.

Our heavy metals removal program offers a reliable solution to address this pressing issue. We understand the challenges of managing industrial wastewater and the importance of meeting regulatory requirements. By using our products, you can be confident that your wastewater treatment program is effective and environmentally responsible, providing peace of mind for your business and the communities you serve.

Metal Removal

Our comprehensive range of products is designed to address the critical issue of heavy metal removal from wastewater. By utilizing our industrial wastewater treatment programs, you can effectively remove heavy metals in all discharge pH ranges, saving time and chemical usage. Ensuring compliance with discharge requirements for constituents such as iron, lead, copper, chromium, nickel, and manganese is essential to prevent environmental contamination and promote sustainable business practices.

Our heavy metals removal program offers a reliable solution to address this pressing issue. We understand the challenges of managing industrial wastewater and the importance of meeting regulatory requirements. By using our products, you can be confident that your wastewater treatment program is effective and environmentally responsible, providing peace of mind for your business and the communities you serve.

Odor Control

Our industrial wastewater treatment solutions include a comprehensive range of odor-masking agents and neutralizers, as well as hydrogen sulfide scavengers and absorbents, which effectively reduce or eliminate unpleasant odors from any source.

Does your wastewater have unpleasant odors? These odors are caused by the presence of volatile organic compounds, such as hydrogen sulfide and ammonia, that can easily escape into the surrounding air. Odor control is vital for various industries, such as paper, refining, natural gas separation and purification, industrial wastewater treatment, and animal and food processing. To tackle severe odors, a combination of operational, mechanical, and chemical treatment technologies may be necessary.

Air Stripper Treatment

Air stripping is a cost-effective and reliable method for treating wastewater odors. Contaminated water is exposed to a counterflow of air in a packed tower to strip out volatile organic compounds (VOCs), which are either discharged or treated. However, pretreatment is crucial for optimal performance when using air strippers for industrial odor control and pollution. For instance, wastewater with high ammonia levels may require pH adjustment before stripping. Moreover, iron, manganese, and bacteria in a water source can lead to scale and fouling within the air stripper, reducing its efficiency and other equipment. Florida WPS offers specialty chemicals, such as iron and manganese stabilizers, scale inhibitors, and biocides, to reduce or eliminate air stripper fouling.

Air strippers are not only critical for odor control but also for health and safety as they can remove hazardous air pollutants like benzene, toluene, ethylbenzene, and xylene. Florida WPS offers a complete range of odor neutralizers, such as hydrogen sulfide scavengers and absorbents, to reduce or eliminate noxious odors from any source. Florida WPS can lower chlorides and sulfates to meet regulatory requirements for discharge or reuse.

Air Stripper Treatment

Air stripping is a cost-effective and reliable method for treating wastewater odors. Contaminated water is exposed to a counterflow of air in a packed tower to strip out volatile organic compounds (VOCs), which are either discharged or treated. However, pretreatment is crucial for optimal performance when using air strippers for industrial odor control and pollution. For instance, wastewater with high ammonia levels may require pH adjustment before stripping. Moreover, iron, manganese, and bacteria in a water source can lead to scale and fouling within the air stripper, reducing its efficiency and other equipment. Florida WPS offers specialty chemicals, such as iron and manganese stabilizers, scale inhibitors, and biocides, to reduce or eliminate air stripper fouling.

Air strippers are not only critical for odor control but also for health and safety as they can remove hazardous air pollutants like benzene, toluene, ethylbenzene, and xylene. Florida WPS offers a complete range of odor neutralizers, such as hydrogen sulfide scavengers and absorbents, to reduce or eliminate noxious odors from any source. Florida WPS can lower chlorides and sulfates to meet regulatory requirements for discharge or reuse.

We Provide Water Solutions For You!

Talk to us today!

Company

Our Services

Location

7901 SW 6th Court, 3rd Floor, Plantation, FL 33324

Mailing Address:

7027 W. Broward Blvd, #337, Plantation, FL 33317